Shenzhen Yihongyuan Hardware Spring Co., Ltd.

Contact:Mr. Gao

Mobile:15914134957

19129341913

Tel:0769-88002550

Fax:0755-22633411

Address:

No. 47,Factory Building,Houting Second Industrial Zone,Shajing Street,Baoan District,Shenzhen

No. 15,Haibin Road,Chang'an Town,Dongguan City

Compared with the spring, the stainless steel hardware spring is actually the same. Both are elastic elements widely used in the mechanical and electronic industries. The spring can undergo large elastic deformation when it is loaded, converting mechanical work or kinetic energy into deformation energy. After unloading, the deformation of the spring disappears and returns to its original state. , which converts deformation energy into mechanical work or kinetic energy. Applicable to the requirements of anti-corrosion, temperature resistance, non-magnetic and other ranges.

The stainless steel hardware spring material must meet the standard YB(T)11-83 Ministry of Metallurgy standard. Commonly used materials are domestic stainless steel 304, 302, 301, 316, 316L, 321.202.201.430.420, and imported Korean Elephant, KOS Korea, etc. T316 is recommended for applications with high corrosion resistance and non-magnetic properties, but has lower mechanical properties than T302/T304. As a widely used steel, T302/T304 is the most commonly used stainless steel hardware spring material because it contains Ni and has superior mechanical properties, corrosion resistance, heat resistance and low temperature strength than Cr. T631J1/T631 is used for heat-resistant springs and springs with high tensile strength after heat treatment, but its corrosion resistance is worse than that of T302/T304.

There are also many choices for the appearance of the material, bare wire, resin-plated spring, wire nickel-plated spring wire, stainless steel hardware spring is divided into bright surface, semi-bright surface, and matte surface. Customers can choose according to the requirements of product precision and aesthetics.

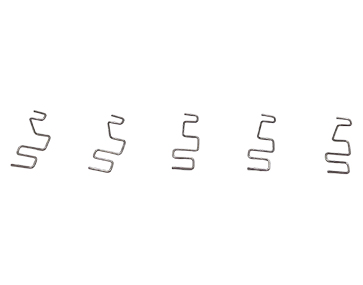

The stainless steel hardware spring has a uniform and beautiful appearance, good formability, uniform elasticity, high plasticity, good fatigue resistance, heat resistance and corrosion resistance. Stainless steel hardware springs can be divided into leaf springs, coil springs, annular springs, truncated cone scroll springs, disc springs, and torsion bar springs according to their shapes. According to the nature of the force, stainless steel hardware springs can be divided into stretching, changing springs, zigzag springs, and compression springs. Ordinary cylindrical springs are widely used because they are simple to manufacture and can be made into various types according to the load conditions.

Generally speaking, the spring should have high elastic limit, fatigue limit, impact toughness and good heat resistance and corrosion resistance. The commonly used materials are referred to above. The cold rolling method is commonly used for spring wires with a diameter of less than 20 mm. Some springs are subjected to strong pressure or polishing after being made, which can improve the bearing capacity of the spring.

Whether it is non-magnetic or weakly magnetic stainless steel hardware spring, it can be widely used in home appliances, electronics, civil, industrial and other products. It is an indispensable and widely used component in the current economic society and industrial society, which promotes the steady development of the social economy.