Shenzhen Yihongyuan Hardware Spring Co., Ltd.

Contact:Mr. Gao

Mobile:15914134957

19129341913

Tel:0769-88002550

Fax:0755-22633411

Address:

No. 47,Factory Building,Houting Second Industrial Zone,Shajing Street,Baoan District,Shenzhen

No. 15,Haibin Road,Chang'an Town,Dongguan City

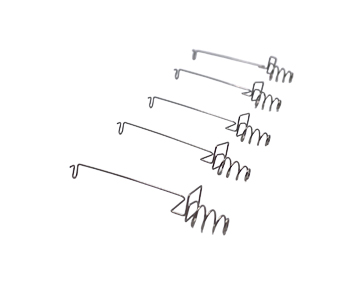

Summary of basic knowledge of stainless steel spring

A stainless steel spring is a mechanical part that uses elasticity to work. Generally made of spring steel. It is widely used in machines and instruments to control the movement of parts, smooth shock or vibration, store energy, measure force, etc.

The spring is just an accumulator. It has the function of storing energy, but it cannot release the energy slowly. To achieve this ability to release slowly, it should be accomplished by "spring + large transmission ratio mechanism", which is common in mechanical watches.

Stainless steel tension spring is an elastic element widely used in the mechanical and electronic industries. The spring can produce large elastic deformation when it is loaded, and convert mechanical work or kinetic energy into deformation energy, and the deformation of the tension spring disappears after unloading. And return to its original state, and convert deformation energy into mechanical work or kinetic energy together.

Generally speaking, the material of stainless steel spring should have high elastic limit, fatigue limit, impact toughness and good heat treatment function. Commonly used are carbon spring steel, alloy spring steel, stainless spring steel, copper alloy and nickel alloy. and rubber etc. The production methods of springs include cold rolling and hot rolling. The diameter of the spring wire is less than 8 mm, and the cold rolling method is generally used, and the hot rolling method is used for the spring wire larger than 8 mm. Some springs are also subjected to strong pressure or shot peening after being made, which can improve the bearing capacity of the spring. The ratio of the load to the deformation of the spring is called the spring stiffness, and the higher the stiffness, the stiffer the spring.